What is composite strapping?

Composite strapping is a type of strapping made from a combination of materials, typically polyester fibers and polymer coatings. This results in a strong and durable strapping solution that is used in various industries for securing heavy loads during transportation.

Importance of corrosion resistance properties

Corrosion resistance properties are crucial when it comes to composite strapping, especially in industries where the strapping is exposed to harsh environments or chemicals. The ability of composite strapping to resist corrosion ensures that it remains strong and reliable even in challenging conditions.

Materials used for corrosion resistance

The materials used in composite strapping, such as polyester fibers and polymer coatings, are specifically chosen for their corrosion resistance properties. These materials are able to withstand rust, degradation, and other forms of corrosion, ensuring the longevity of the strapping.

Advantages of corrosion resistance in composite strapping

Corrosion resistance in composite strapping offers several advantages, including increased durability, reliability, and safety. This is especially important in industries where the strapping is used to secure heavy and valuable loads during transportation.

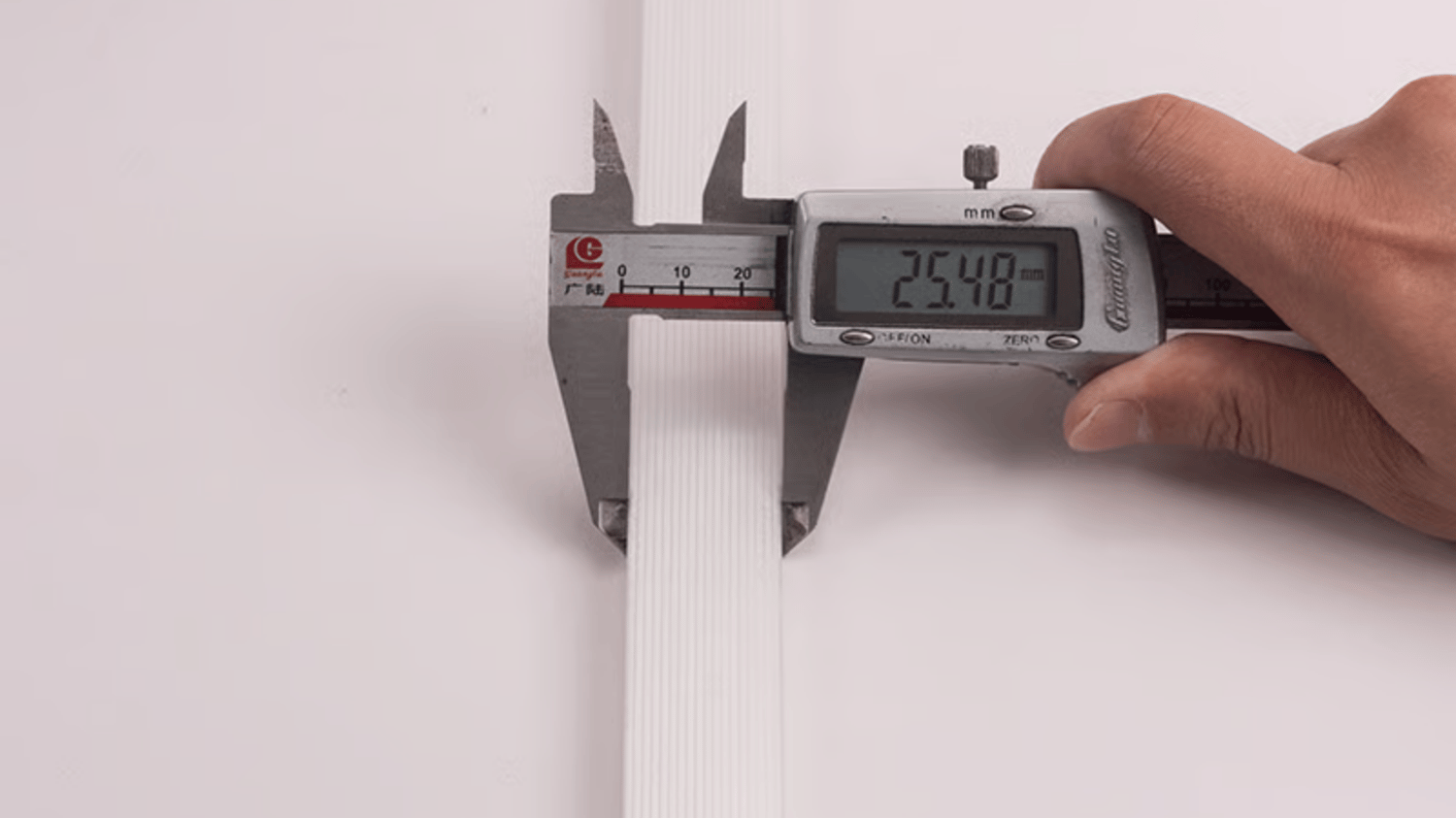

Testing methods for corrosion resistance

Manufacturers of composite strapping use various testing methods to evaluate the corrosion resistance properties of their products. These tests include exposure to extreme temperatures, moisture, and chemicals to ensure that the strapping meets industry standards for corrosion resistance.

Applications of corrosion-resistant composite strapping

Corrosion-resistant composite strapping is used in a wide range of industries, including shipping, logistics, construction, and manufacturing. Its ability to withstand corrosion makes it an ideal choice for securing loads in both indoor and outdoor environments.

Comparing corrosion resistance with other types of strapping

When compared to other types of strapping, such as steel or plastic, composite strapping offers superior corrosion resistance properties. This makes it a preferred choice for industries where corrosion is a major concern.

Benefits of investing in corrosion-resistant composite strapping

Investing in corrosion-resistant composite strapping can result in cost savings in the long run. The strapping's durability and longevity reduce the need for frequent replacements, ultimately saving money for businesses in the long term.

Factors to consider when choosing corrosion-resistant strapping

When choosing corrosion-resistant composite strapping, it is important to consider factors such as the type of load being secured, environmental conditions, and industry regulations. This ensures that the strapping meets the specific requirements of the application.

Conclusion

Composite strapping with corrosion resistance properties is a reliable and durable solution for securing heavy loads during transportation. Its ability to withstand corrosion, along with its numerous advantages, makes it a preferred choice for industries where reliability and safety are paramount.